Contact Us

STATEN ISLAND FIBERAMA

STATEN ISLAND FIBERAMA

stainless steel wire mesh is known for its versatility. It finds applications in various industries. From construction to food processing, its benefits are numerous.

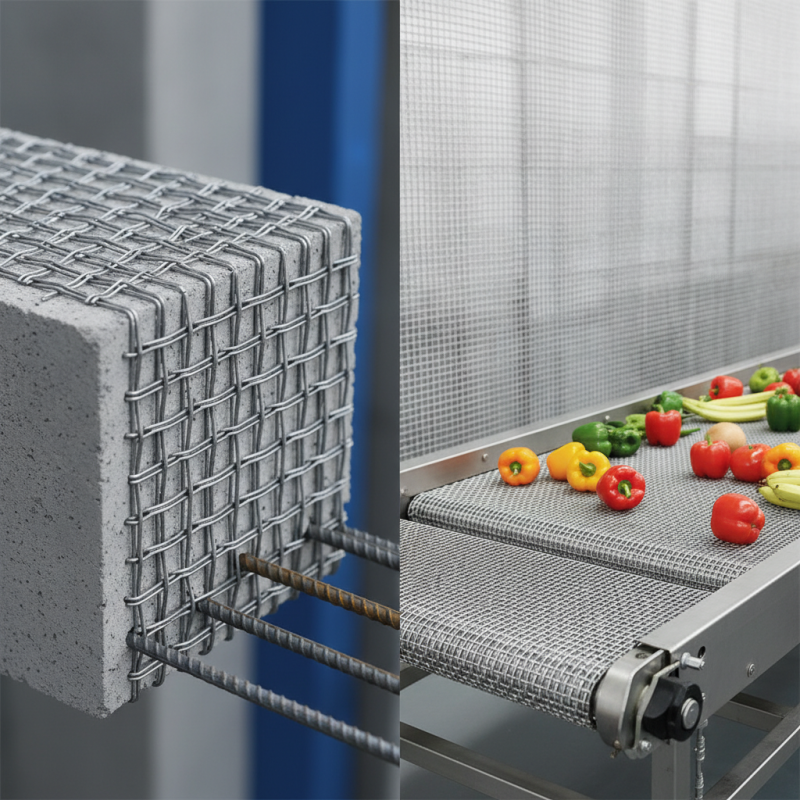

In construction, stainless steel wire mesh provides strength and durability. It can reinforce concrete structures. Additionally, it acts as a protective barrier in safety applications. In the food industry, it's crucial for hygiene. Its resistance to corrosion ensures the safety of food products.

However, the cost of stainless steel wire mesh can be high. This might deter some potential users. Many may find alternatives cheaper but less reliable. Balancing cost and quality is challenging. Yet, understanding the true value of stainless steel wire mesh in specific applications can lead to better decisions.

Stainless steel wire mesh is widely used in industrial settings for various applications. Its strength and corrosion resistance make it ideal for filtration. Factories often use it to separate solids from liquids or gases. This ensures processes run smoothly and maintains product quality. It can handle high temperatures and extreme environments, making it versatile.

In construction, stainless steel wire mesh serves structural purposes. It reinforces concrete, providing additional strength and durability. This application is essential for ensuring building safety. However, improper installation may lead to weaknesses. Regular inspections are necessary to ensure its integrity over time.

Additionally, stainless steel wire mesh can be seen in food processing. It ensures safe and hygienic handling of food products. The mesh prevents contaminants from entering production lines. However, cleanliness must be maintained to avoid potential contamination. This attention to detail is crucial in preserving food quality and safety.

Stainless steel wire mesh is widely used in filtration systems due to its incredible durability and corrosion resistance. This material is ideal for filtering liquids and gases, as it can withstand high pressure and temperature. The fine openings in the mesh effectively trap particles while allowing the free flow of fluids. These characteristics make it a go-to choice in industries like food processing and pharmaceuticals.

One key benefit of stainless steel wire mesh is its longevity. Unlike plastic or other materials, it does not degrade over time. This means less replacement and lower maintenance costs overall. However, it is essential to choose the right mesh size for the specific application. A mesh that is too fine may clog quickly, while one that is too coarse may allow unwanted particles through. Finding the right balance can be challenging yet rewarding.

Another benefit lies in its adaptability. Stainless steel wire mesh can be easily customized to fit various filtration needs. Different patterns and thicknesses cater to specific requirements. Still, one must consider the implications of such modifications. Every change can affect the filtration efficiency. Continuous evaluation of filtration systems using stainless steel wire mesh is crucial for optimal performance.

Stainless steel wire mesh stands out for its remarkable corrosion resistance. This quality makes it a preferred choice in various environments. In industrial settings, exposure to moisture and chemicals is common. Stainless steel can withstand these challenges without degrading. This durability ensures that the wire mesh maintains its integrity over time.

In addition to durability, the aesthetic appeal of stainless steel wire mesh is noteworthy. It offers a clean, polished look that suits both modern and traditional designs. However, it is essential to consider the right grade of stainless steel for specific applications. Not all stainless steels provide the same level of corrosion resistance. Using lower quality materials can lead to unforeseen maintenance issues.

One should also be aware of the limitations. While stainless steel is resistant to rust, it is not entirely immune to corrosion. In aggressive environments, even the best mesh may require protection. Regular maintenance can help prolong its lifespan. Understanding these factors can aid in making better decisions regarding its use.

Stainless steel wire mesh is widely utilized across various industries due to its excellent corrosion resistance and strength. This chart illustrates the percentage of applications for stainless steel wire mesh in key sectors, highlighting its versatility and reliability.

When it comes to wire mesh materials, stainless steel stands out for its unique properties. It exhibits exceptional corrosion resistance, making it ideal for outdoor applications. This can be seen in structures like fences and architectural designs. Stainless steel wire mesh is durable and reliable, often lasting longer than alternatives like aluminum or plastic. However, its higher cost can be a drawback for some users.

Comparing stainless steel to other materials highlights its strengths. Aluminum is lighter but less durable, making it less suitable for heavy-duty applications. Plastic is inexpensive but can degrade quickly under UV exposure. Stainless steel retains structural integrity under extreme conditions. Its tensile strength is often unmatched. This makes it a preferred choice in industries such as construction, food processing, and filtration. Yet, the weight of stainless steel can complicate transportation and installation.

For those considering wire mesh options, it’s crucial to assess specific needs. While stainless steel offers durability and strength, its cost and weight may not suit every project. Balancing performance with practical limitations is essential. Stainless steel shines in resilience, but it’s not always the perfect solution for every situation.

Stainless steel wire mesh offers numerous advantages in agriculture. It is often used for crop protection and fencing. The mesh allows air and sunlight to reach plants while keeping pests away. According to industry reports, nearly 30% of farmers use wire mesh for effective pest control. This reduces crop loss and increases yield.

Another application is in soil separation. Farmers utilize stainless steel mesh to prevent soil erosion. It helps retain moisture and nutrients by keeping the soil intact. A study indicates that proper soil management can boost crop production by 15%. However, this requires careful installation. Many farmers overlook the proper use of mesh, leading to suboptimal results.

Farmers also favor wire mesh for animal enclosures. It minimizes predation risk and enhances livestock safety. However, not all steel mesh products are created equal. Some lower-quality options may rust quickly in humid environments. This is a concern that needs attention. Long-term benefits depend on selecting the right materials and maintenance practices.

© 2025 Fiberama All Rights Reserved.